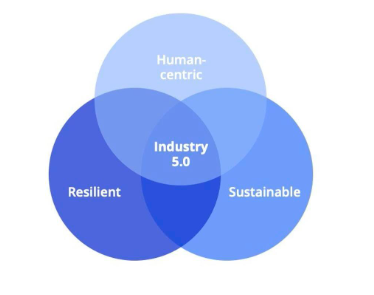

Every revolution results in a more evolved system and, as a result, its output. The spheres of industry and academia are no exception and must also be tightly coupled. Industry 5.0, also known as the Fifth Industrial Revolution, is a new and developing era of industrialisation in which humans collaborate with modern technology and artificial intelligence-powered robots to improve workplace processes. Although robots are more consistent than humans and perform better at precision tasks, they are rigid and lack the adaptability and critical thinking skills that distinguish us as humans.

Fundamentally, Industry 5.0 necessitates a socio-technical development that adds a personal human touch to the Industry 4.0 pillars of automation and efficiency, refining collaborative interactions between humans and machines using sophisticated technologies such as the Internet of Things (IoT) and big data. Compared to Industry 4.0, Industry 5.0 introduces improved automation and, more importantly, an integrated mechanism via a human-centric approach for increased resilience and a broader focus on sustainability. Although AI is prevalent in various contexts on data and other functional models, human intelligence drives derives, and interprets the essence of AI activity. AI is heavily reliant on Actual Intelligence (AI) from human intelligence. Human intervention is thus the foundation for the Industry 5.0 revolution.

1. Human-Centric

Industry 5.0 includes a strategy that moves people from being seen as resources to being genuine assets. In effect, this means that rather than people serving organisations, organisations will serve people by adding value and continuing the association.

2. Resilience

The recent repercussions, such as the COVID-19 outbreak and international supply constraints, have taught us a lot. As a result, instead of focusing on growth, profit, and efficiency, organisations must now seek to anticipate and respond to any crisis to maintain stability during difficult times and make the organisation and process more resilient.

3. Sustainability

Regarding sustainability, Industry 5.0 aspires to improve our workplace by creating rules, innovations, and practices as part of the solution rather than a problem.

Academia 5.0 for Industry 5.0

Industry 5.0 will not only provide significant benefits to industry and academia, but it will also present some unique challenges. One such challenge to academia is preparing students for jobs in the future. Because future job opportunities will be based on advanced technologies, students must be proficient in coding, data analytics, robotics & automation, sensor technology, semiconductors, smart materials, additive manufacturing, mathematical modelling & simulation, quantum computing, and machine learning. This necessitates a major concentration on faculty upskilling and suitable curricula development.

Furthermore, this may necessitate the development of new pedagogical approaches, the incorporation of technology into the classroom, the adoption of new assessment methods to test students’ knowledge and skills, social and emotional development, sustainability, personalised learning, a collaborative approach, and, most importantly, ethical considerations. Learners remain in the centre, with faculty serving as knowledge facilitators rather than information providers. This learner-centric approach is consistent with Industry 5.0’s collaborative character. Academia 5.0 can help by supporting work-integrated learning programs, internships, projects, and startup creation. These alternatives educate students for their professional careers and assist the industry in obtaining a skilled workforce for their specific needs. Furthermore, faculty who obtained their qualifications in previous years must develop abilities in current and futuristic technologies with enthusiasm and deep curiosity, which will become the key to aiding the student community in meeting future demands.

Developing future-ready skills is one of the fundamental synergies between Industry 5.0 and Academia 5.0. As the workforce becomes more adaptive and imaginative, education must foster student collaboration and creativity through activities such as project-based learning and real-world problem-solving. In a nutshell, Industry 5.0 allows robots and automation to collaborate with humans to focus on value-added operations, taking product customisation to a new level. Tailoring items to individual needs, including electronics, automobiles, and more, while adding a personal, human touch to expand the offers produced by Industry 4.0.

Views expressed by Dr. Sudheer Reddy, Dean – International Relations, Professor- Mechanical Engg, Nitte Meenakshi Institute of Technology, Bangalore